Experience Precision and Productivity with

Production Mastery

Register For Free Trial

Managing production processes efficiently is crucial for manufacturing and production companies. eresource On-Demand ERP provides comprehensive tools to handle various aspects of production, from creating Bill of Materials (BOM) to tracking material consumption and managing wastage. Below, you'll find an overview of these processes within the eresource On-Demand ERP :

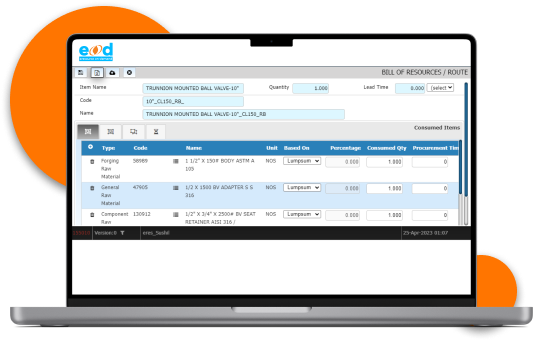

Bill of Material (BOM)

- BOM is a structured list of all components, raw materials, and sub-assemblies required to manufacture a finished product.

- In eresource On-Demand ERP, you can create and maintain BOMs for different products

- Each BOM includes a list of materials, quantities, and their hierarchical structure

- BOMs help in accurate production planning and cost estimation.

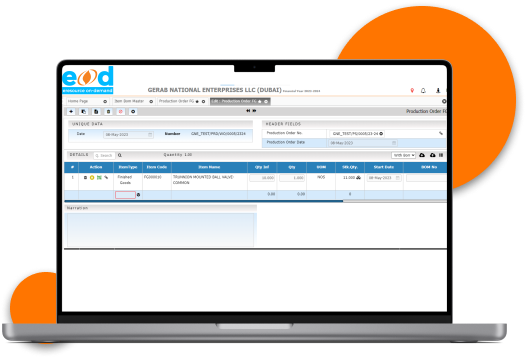

Production Work Order

- A production work order is a document that authorizes the production department to start manufacturing a specific quantity of a product.

- In eresource On-Demand, you can create work BOM and production schedule.

- Work orders include details like production quantity, priority and deadlines.

Job Card

- Job cards are used to track the progress of work on the shop floor.

- eresource On-Demand ERP allows you to generate job cards linked to specific work orders.

- Job cards include information about the assigned workers, machine usage, and time tracking

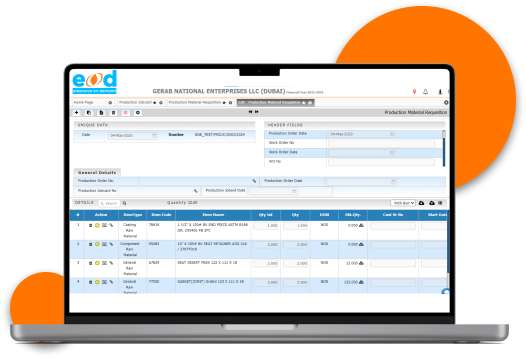

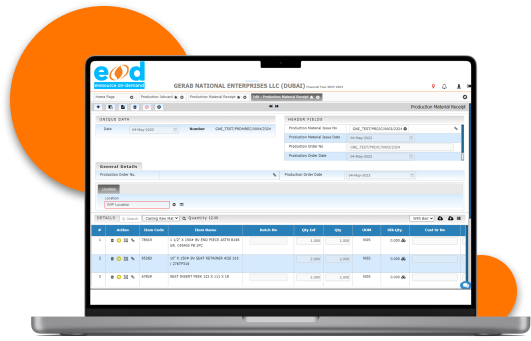

Production Material Requisition

- Material requisitions are used to request the inventory for a necessary materials from the in production job.

- In the eresource On-Demand, you can create material requisitions directly from the job cards or work orders.

- Requisitions list the materials needed, quantities and requested delivery date.

Material Receipt

- Material receipts document the receipt of materials from suppliers or the inventory.

- In eresource On-Demand, you can receive materials against purchase orders, material requisitions, or directly for production.

- Receipts update inventory levels and ensure accurate tracking of stock.

Production Yield Output

- Production yield represents the quantity of finished products successfully manufactured.

- In eresource On-Demand, you can track production yield against the work orders.

- Understanding yield helps in measuring production efficiency and identifying areas for improvement.

Material Consumption

- Material consumption records the usage of raw materials and components during

- eresource On-Demand ERP allows you to record material consumption against specific work orders.

- Accurate tracking of material consumption is crucial for cost control.

Wastage Management

- Wastage refers to materials that are discarded or considered unusable during production.

- eresource On-Demand ERP enables you to record and track wastage.

- Analyzing wastage helps in minimizing material losses and optimizing production processes.

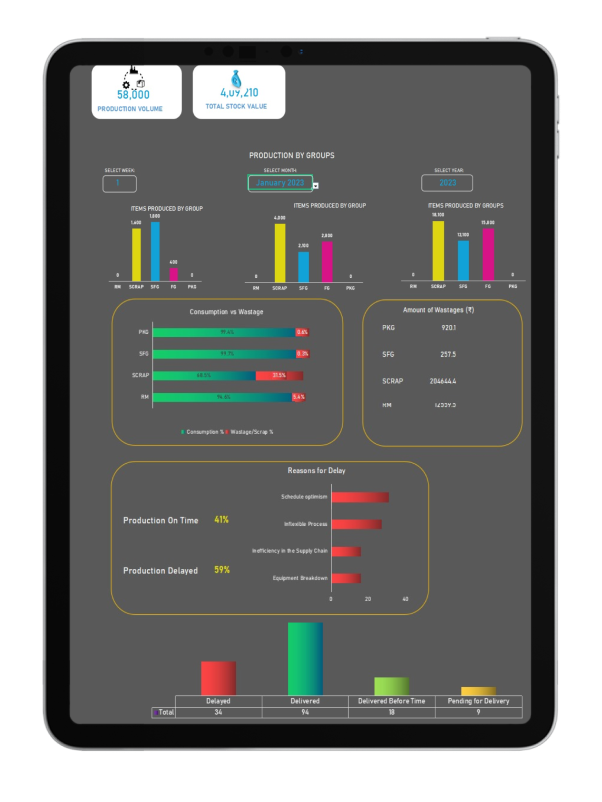

Reporting and Analysis

- Utilize the reporting and analytics features in the ERP system to generate production-related reports.

- Analyze production efficiency, material utilization, and cost variances to make informed decisions.