Project Inventory

Management

Register For Free Trial

In the dynamic world of business, efficient management of site and warehouse inventory is paramount to success. With eresource On-Demand, you have a comprehensive solution at your fingertips, offering effortless control, optimization, and real-time visibility over your inventory across multiple sites and warehouses.

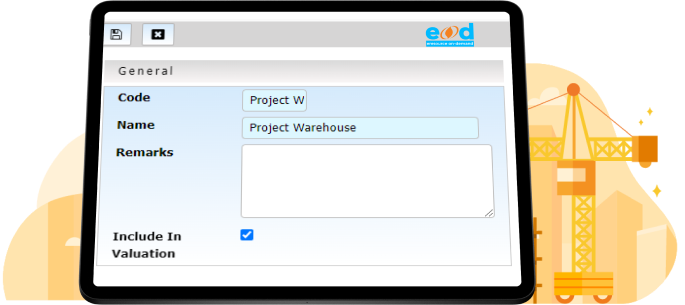

Store Creation

- Efficient management of materials and equipment is a critical component of successful contracting projects. eresource On-Demand's "Stores" management feature allows you to maintain control and oversight of all project-related inventory, ensuring that the right materials are available at the right time.

Key Features

Inventory Tracking:

Monitor and track the availability of materials, equipment, and supplies in real-time.

Inventory Categories:

Organize items into categories for easy identification and efficient storage

Requisition Management:

Enable project teams to raise requisitions for required materials and equipment.

Issue and Return:

Manage the issuance of items to project sites and their return, ensuring accurate inventory records.

Inventory Reports:

Access detailed reports and analytics on inventory usage and availability.

Benefits

Optimized Inventory

Ensure that the right materials and equipment are always available for project tasks.

Reduced Delays

Prevent project delays by maintaining adequate stock levels and managing requisitions efficiently.

Cost Control

Avoid unnecessary purchases and costs by optimizing inventory usage.

Inventory Transparency

Keep stakeholders informed about the status of project materials and equipment.

Streamlined Operations

Improve project efficiency and reduce downtime with well-managed stores.

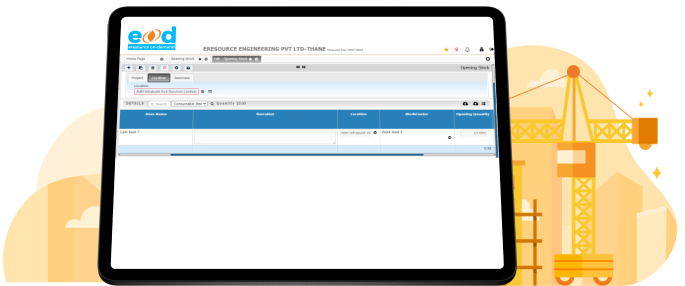

Opening Stock

- A seamless start is crucial for the success of any contracting project. The "Opening Stock" transaction in eresource On-Demand is your gateway to begin your project with a clear understanding of the inventory you have on hand.

Key Features

Inventory Assessment:

Review and record the inventory items you have on hand at the beginning of a project.

Categorization:

Organize opening stock items into categories for easy management.

Quantity Verification:

Verify the quantity of each item to ensure accuracy.

Valuation:

Assign values to each item in your opening stock, allowing for accurate project cost calculations.

Transparency:

Maintain a transparent record of what resources you bring into the project.

Integration:

Seamlessly integrate your opening stock data with project planning and execution.

Benefits

Accurate Project Budgeting

Start your project with a clear understanding of your initial resources for accurate budgeting.

Timely Procurement

Avoid unnecessary duplication by ensuring you don't order items you already have.

Resource Allocation

Plan your project resource allocation with precision based on opening stock data.

Cost Control

Maintain financial transparency from the project's inception.

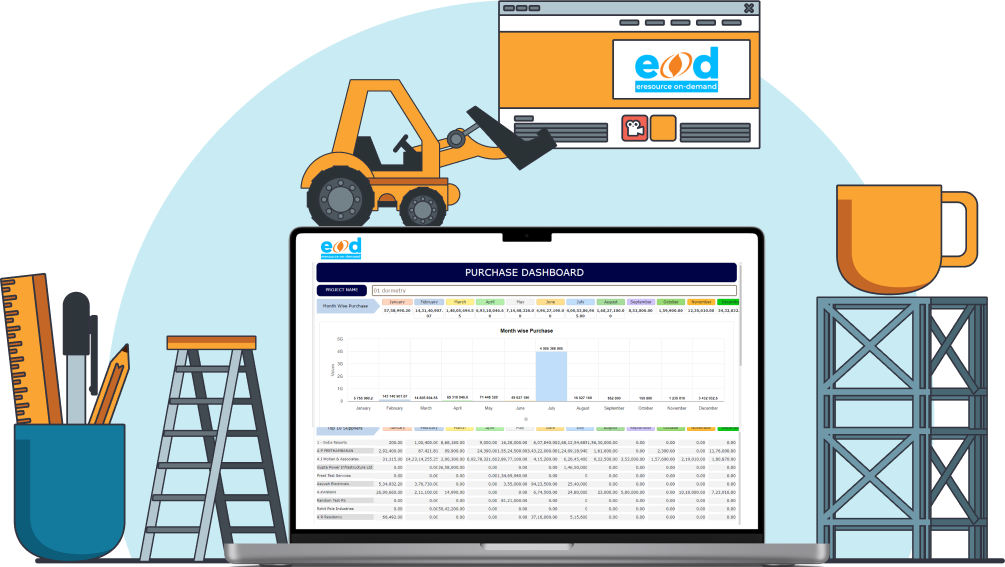

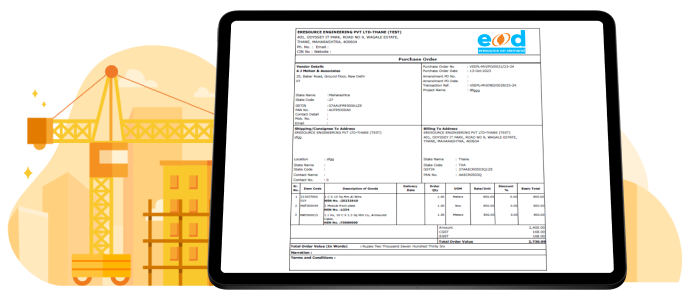

Purchase Order

- Efficient procurement and contract management are crucial in the world of contracting. eresource On-Demand's "Purchase Order" transaction is your gateway to seamlessly initiate and manage the procurement of materials, equipment, and services required for your contracting projects.

Key Features

Purchase Request:

Easily create purchase requests specifying the required items, quantities, and delivery deadlines.

Supplier Selection:

Connect with trusted suppliers to obtain competitive quotations for the requested items.

Comparative Analysis:

Evaluate supplier quotations to make informed decisions based on cost, quality, and delivery times.

Approval Workflows:

Implement approval processes to ensure that purchase orders align with project budgets and contractual terms.

Order Generation:

Generate purchase orders with all necessary details, including terms and conditions, delivery schedules, and payment terms

Real-Time Tracking:

Monitor the status of purchase orders and deliveries, ensuring on-time receipt of materials.

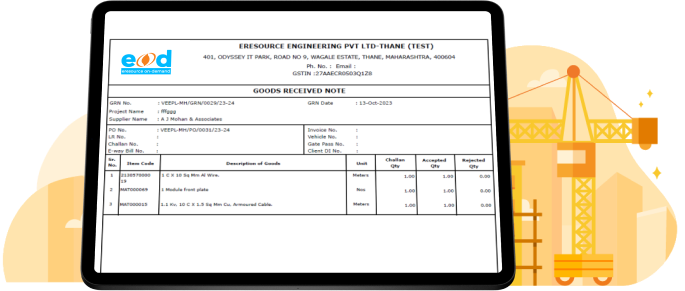

GRN

- Efficiently managing the receipt of goods and materials is pivotal for the success of any contracting project. The "Goods Receipt Note (GRN)" transaction in eresource On-Demand simplifies the process of verifying and recording received items, enhancing accuracy and accountability.

Key Features

Verification:

Verify the quantity and quality of goods received against purchase orders or requisitions.

Material Inspection:

Conduct material inspections to ensure compliance with project specifications.

Quality Control:

Enforce quality control measures to maintain project standards.

Documentation:

Generate comprehensive GRN documents for record-keeping and auditing purposes.

Vendor Accountability:

Create accountability by recording vendor details and maintaining a history of vendor performance.

Inventory Update:

Automatically update inventory records to reflect the received goods.

Benefits

Accuracy

Ensure that received materials match the project requirements and specifications.

Documentation

Maintain detailed records for auditing and compliance purposes.

Vendor Evaluation

Collect data for evaluating vendor performance and reliability.

Resource Tracking

Keep accurate inventory records for project materials and equipment.

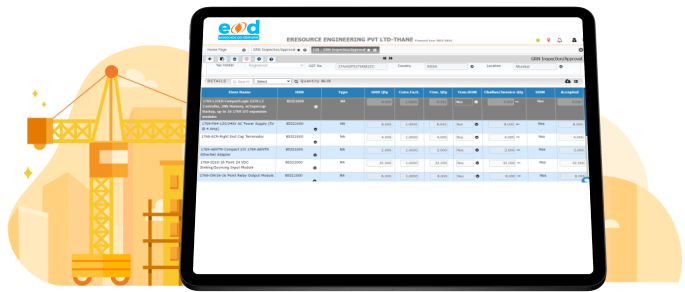

GRN Inspection

- The quality and accuracy of received goods and materials play a pivotal role in the success of contracting projects. The "Goods Receipt Note (GRN) Inspection" process within eresource On-Demand ensures that every item received aligns with project specifications and quality standards.

Key Features

Quality Verification:

Inspect goods and materials to verify their quality, condition, and compliance with project specifications.

Inspection Criteria:

Define specific criteria and quality standards against which items are inspected.

Documentation:

Record detailed inspection results, including any non-conformities or issues identified.

Exception Handling:

In cases of non-compliance, the system allows for documenting exceptions and initiating corrective actions.

Benefits

Quality Assurance

Ensure that all received items meet project-specific quality standards.

Accurate Record-Keeping

Maintain comprehensive records of inspections for auditing and compliance purposes.

Issue Resolution

Quickly identify and address non-compliance or quality issues.

Project Integrity

Uphold project quality and safety standards by conducting thorough inspections.

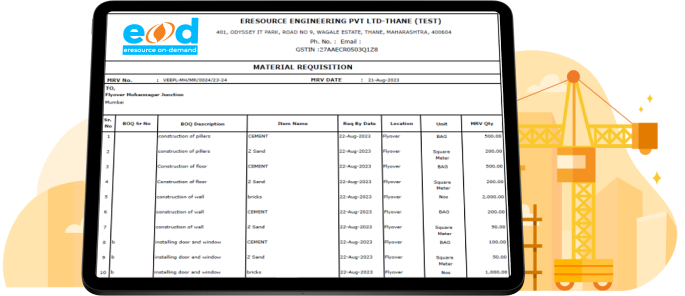

Material Requisition

- Efficient material requisition is the backbone of successful project execution in contracting. eresource On-Demand's "Material Requisition" process simplifies the request and approval of materials, ensuring that the right resources are available at the right time.

Key Features

Material Request:

Project teams can raise requisitions for materials, equipment, or supplies required for project tasks.

Approvals:

Implement an approval workflow to ensure that requisitions are reviewed and approved by the appropriate personnel.

Budget Compliance:

Verify that the requested materials align with the project budget and do not exceed allocated resources.

Vendor Selection:

Choose the preferred vendors or suppliers based on quality, cost, and reliability.

Integration:

Seamlessly integrate material requisitions with project planning and procurement.

Benefits

Resource Availability

Ensure that the necessary materials are available for project tasks, preventing delays.

Budget Control

Manage project budgets effectively by aligning requisitions with allocated resources.

Approval Workflow

Implement control mechanisms to ensure that requisitions meet project needs.

Vendor Accountability

Optimize vendor selection to secure quality resources at competitive prices.

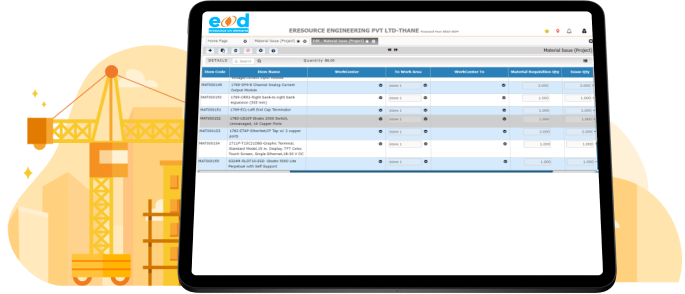

Material Issue

- Effective material issuance is crucial for project progress and cost control in contracting. The "Material Issue" process in eresource On-Demand streamlines the allocation of materials to project tasks, ensuring resource availability and accurate project tracking.

Key Features

Resource Allocation:

Allocate materials, equipment, and supplies to specific project tasks or work orders.

Project Tracking:

Update project records in real-time to reflect issued materials and their impact on project progress.

Approval Workflow:

Implement approval workflows to ensure that material issuance aligns with project requirements.

Inventory Deduction:

Automatically update inventory records to reflect the materials issued.

Benefits

Resource Availability

Ensure that project teams have access to the materials they need to complete their tasks efficiently.

Cost Control

Accurately track the usage of materials, preventing overuse and controlling project costs.

Project Progress

Keep project records up-to-date, providing a clear picture of task completion and resource usage.

Transparency

Maintain a transparent record of material issuance for auditing and compliance purposes.

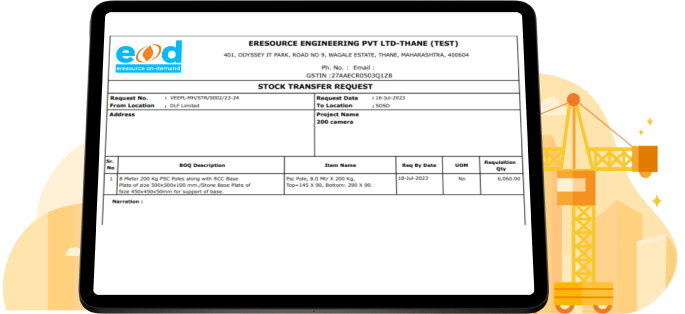

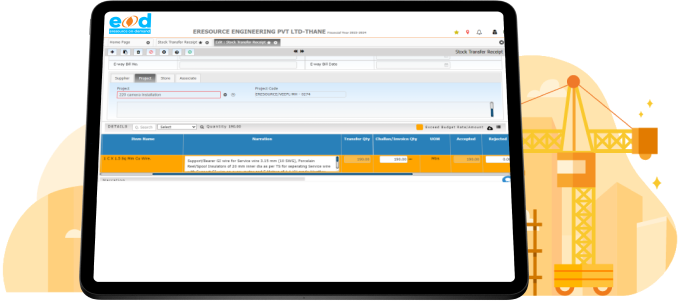

Stock Transfer Request

- Efficiently managing stock transfers is a critical aspect of contracting projects. The "Stock Transfer Request" process in eresource On-Demand simplifies the transfer of materials and resources between project locations or teams, ensuring resources are in the right place at the right time.

Key Features

Resource Request:

Project teams can raise requests for stock transfers to move materials, equipment, or supplies between project locations.

Approval Workflow:

Implement an approval process to ensure that stock transfer requests are reviewed and approved by the appropriate personnel.

Inventory Management:

Automatically update inventory records to reflect the materials' new location after the transfer.

Resource Tracking:

Keep accurate records of stock transfers for project materials and equipment.

Benefits

Resource Availability

Ensure that materials are available where they are needed, preventing project delays and improving efficiency.

Approval Control

Implement control mechanisms to ensure that stock transfers align with project needs and budget.

Inventory Accuracy

Keep inventory records up to date to reflect the materials' location accurately.

Resource Optimization

Optimize resource allocation by redistributing materials as required.

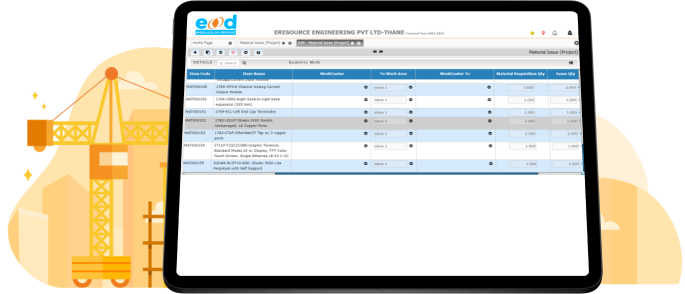

Stock Transfer Issue

- Effective material issuance is crucial for project progress and cost control in contracting. The "Material Issue" process in eresource On-Demand streamlines the allocation of materials to project tasks, ensuring resource availability and accurate project tracking.

Key Features

Resource Allocation:

Allocate materials, equipment, and supplies to specific project tasks or work orders.

Quantity Control:

Monitor and control the quantity of materials issued to prevent overuse or shortages.

Project Tracking:

Update project records in real-time to reflect issued materials and their impact on project progress.

Approval Workflow:

Implement approval workflows to ensure that material issuance aligns with project requirements.

Inventory Deduction:

Automatically update inventory records to reflect the materials issued.

Benefits

Resource Availability

Ensure that project teams have access to the materials they need to complete their tasks efficiently.

Cost Control

Accurately track the usage of materials, preventing overuse and controlling project costs.

Project Progress

Keep project records up-to-date, providing a clear picture of task completion and resource usage.

Transparency

Maintain a transparent record of material issuance for auditing and compliance purposes.

Stock Transfer Receipt

- Efficiently receiving materials and resources from stock transfers is crucial for seamless project operations in contracting. The "Stock Transfer Receipt" process in eresource On-Demand simplifies the reception of transferred materials, ensuring that they are correctly accounted for and available for immediate use.

Key Features

Receiving Confirmation:

Confirm the receipt of materials and resources from stock transfers, matching them with the associated transfer request.

Quantity Verification:

Ensure that the quantity and condition of received materials align with the transfer request and project requirements.

Inventory Update:

Automatically update inventory records to reflect the newly received materials' location and availability.

Documentation:

Generate comprehensive stock transfer receipt documents for record-keeping and auditing purposes.

Resource Allocation:

Allocate received materials to specific project tasks or work orders as needed.

Benefits

Resource Availability

Guarantee that the materials transferred are readily available for project tasks, reducing downtime.

Inventory Accuracy

Maintain precise inventory records by accurately reflecting the received materials' location.

Documentation

Keep detailed records for auditing and compliance purposes, ensuring transparency and accountability.

Resource Allocation

Optimize the allocation of received materials to tasks, enhancing project efficiency.

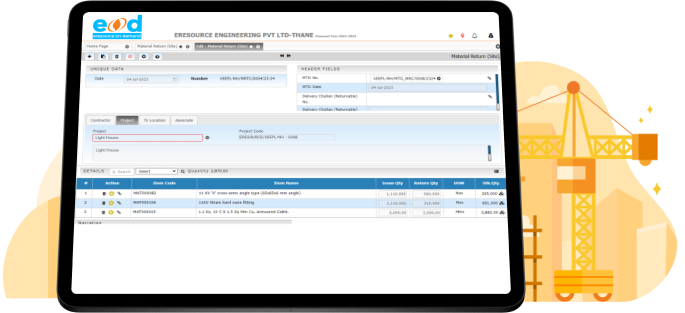

Material Return

- Efficiently managing material returns is a vital component of successful contracting projects. The "Material Return" process in eresource On-Demand simplifies the return of materials, equipment, or supplies, ensuring a smooth and organized process.

Key Features

Return Request:

Project teams can initiate material return requests for items that are no longer needed or for those that do not meet project requirements.

Approval Workflow:

Implement an approval process to ensure that return requests are reviewed and approved by the appropriate personnel.

Return Verification:

Verify the condition and quantity of the returned items to ensure they meet the criteria for acceptance.

Inventory Update:

Automatically update inventory records to reflect the returned materials' availability.

Benefits

Resource Efficiency

Ensure that unused or non-compliant materials are returned and can be allocated to other tasks or projects.

Controlled Process

Implement control mechanisms to ensure that return requests align with project needs.

Inventory Accuracy

Keep inventory records accurate by updating the status and availability of returned materials.

Transparency

Maintain transparent records for auditing and compliance purposes, ensuring accountability.

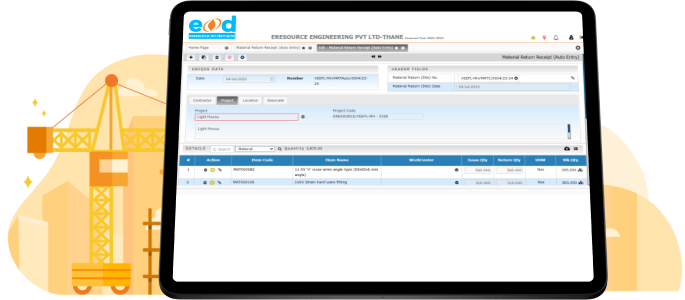

Material Return Receipt

- Accurate material return receipt is essential for effective resource management in contracting projects. The "Material Return Receipt" process in eresource On-Demand simplifies the verification and recording of returned materials, ensuring they are correctly documented and available for future use.

Key Features

Material Return Receipt:

AConfirm the receipt of materials returned from projects or tasks, matching them with the associated return request.

Receipt Confirmation:

Confirm the receipt of materials returned from projects or tasks, matching them with the associated return request.

Quantity and Condition Verification:

Ensure that the quantity and condition of received materials align with the return request and project requirements.

Inventory Update:

Automatically update inventory records to reflect the availability and status of the received materials.

Documentation:

Generate comprehensive material return receipt documents for record-keeping and auditing purposes.

Resource Allocation:

Allocate received materials to specific project tasks or work orders as needed.

Benefits

Resource Availability

Ensure that returned materials are properly documented and available for future use, preventing waste and enhancing efficiency.

Inventory Accuracy

Maintain accurate inventory records by reflecting the status and availability of received materials.

Documentation

Keep detailed records for auditing and compliance purposes, ensuring transparency and accountability.

Resource Allocation

Optimize the allocation of returned materials to tasks, enhancing project efficiency.

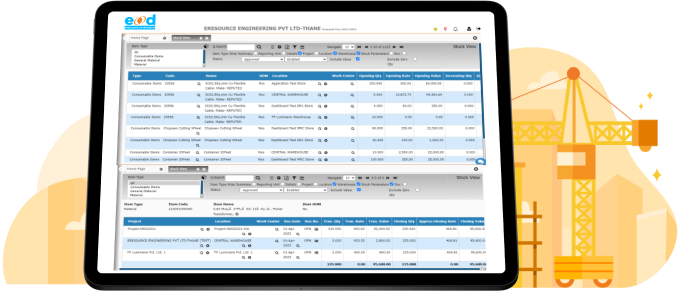

Stock Report

- The "Stock Report" feature in eresource On-Demand offers valuable insights into your material inventory, ensuring that you have the right resources available for your contracting projects. This reporting tool provides a comprehensive view of your stock levels, helping you make informed decisions and maintain efficient resource allocation.

Key Features

Real-time Visibility:

Instantly access accurate information about your stock levels and the availability of materials and resources.

Customization:

Tailor stock reports to suit your specific project requirements and parameters.

Multiple Views:

View stock information by location, project, or material type, allowing for a detailed analysis of your resources.

Inventory Trends:

Analyze historical data to identify usage trends and plan for future project needs.

Export Options:

Export stock reports in various formats for easy sharing and analysis.

Benefits

Resource Availability

Ensure that materials and resources are readily available for your projects, minimizing delays and downtime.

Data-Driven Decisions

Use the insights from stock reports to make informed decisions about resource allocation and project planning.

Cost Control

Avoid overstocking or shortages by maintaining an optimal level of resources.

Auditing and Compliance

Keep detailed records of stock levels and changes for auditing and compliance purposes.